In motion control refers to the technology and techniques used to regulate and manage the movement of mechanical systems. It involves precise control over speed, position, torque, and acceleration of various components in a system. This article will explain how in motion control works and its importance in making data-driven decisions.

The Basics of In Motion Control

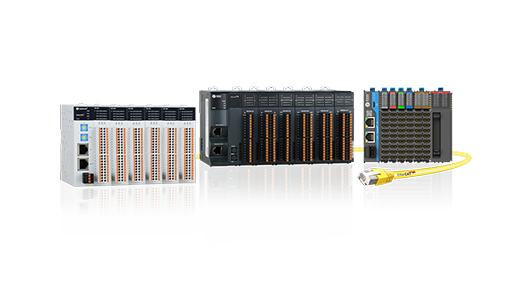

In motion control relies on a combination of hardware and software components to achieve accurate movement control. The hardware includes motors, sensors, drives, controllers, and actuators that work together to execute specific movements based on input commands. The software component consists of algorithms that interpret these commands into motor actions.

By utilizing feedback from sensors such as encoders or resolvers, the controller can continuously monitor the actual position or speed of the system’s moving parts. It compares this information with the desired values provided by an operator or an automated program.

The controller then adjusts the power supplied to the motor through a drive unit accordingly to ensure that any deviations are corrected promptly. This closed-loop feedback mechanism allows for precise positioning accuracy and dynamic response capabilities.

Leadshine: A Leading Provider in In Motion Control

One prominent player in the field of in motion control is Leadshine Technology Co., Ltd., which specializes in developing high-performance stepper drives, servo drives, integrated motors, motion controllers, etc.

Leadshine’s products offer advanced features such as microstepping technology for smoother movements at low speeds and anti-resonance algorithms that minimize vibrations during operation. Their intelligent servo drives provide excellent torque performance while maintaining high precision positioning accuracy.

With their extensive experience in industrial automation applications across various industries like robotics, CNC machines, packaging equipment,and more; Leadshine has established itself as a trusted provider of reliable and efficient in motion control solutions.

Industrial Controls Solutions: Enhancing Efficiency and Productivity

In motion control is a crucial component of industrial controls solutions, which aim to optimize the performance and efficiency of manufacturing processes. By implementing data-driven decisions based on real-time feedback from sensors, businesses can achieve higher productivity, reduce downtime, and improve product quality.

Industrial controls solutions enable predictive maintenance by continuously monitoring the health of machines through various sensors. This allows for timely repairs or replacements before critical failures occur, minimizing costly downtime.

Furthermore, these systems facilitate seamless integration with other automation technologies such as robotics or computer vision systems. The ability to synchronize movements between different components enhances overall system performance and flexibility.

In Conclusion

In motion control plays a vital role in achieving precise movement control in mechanical systems. With companies like Leadshine providing advanced products and industrial controls solutions offering data-driven decision-making capabilities, industries can enhance their efficiency, productivity,and reliability while reducing costs. Embracing this technology opens up new possibilities for automation across various sectors.