Have you ever wondered how we can make inspections more efficient and accurate? Well, look no further than the inspection robot. This innovative technology is changing the game when it comes to inspecting various industries and ensuring quality control.

The Power of Inspection Robot

The inspection robot is equipped with advanced sensors and cameras that allow it to navigate through complex environments and gather data in real-time. Whether it’s inspecting pipelines, manufacturing facilities, or even hazardous areas, this robotic solution provides a safe and reliable alternative to human inspectors.

With its ability to access hard-to-reach places and withstand harsh conditions, the inspection robot eliminates potential risks for workers while delivering precise results. It can detect defects, leaks, or any other anomalies that may compromise safety or efficiency.

Oneway: Individualizing Services for Clients

In addition to revolutionizing inspections, companies like Oneway are taking advantage of technology advancements to provide individualized services for their clients. By combining artificial intelligence with personalized customer experiences, Oneway ensures that each client receives tailored solutions based on their specific needs.

Oneway’s intelligent algorithms analyze vast amounts of data collected by inspection robots during the evaluation process. This allows them to identify patterns and trends unique to each client’s operations. With this information at hand, they can offer customized recommendations aimed at optimizing performance and reducing costs.

Chassis Robotics: Enhancing Efficiency in Manufacturing

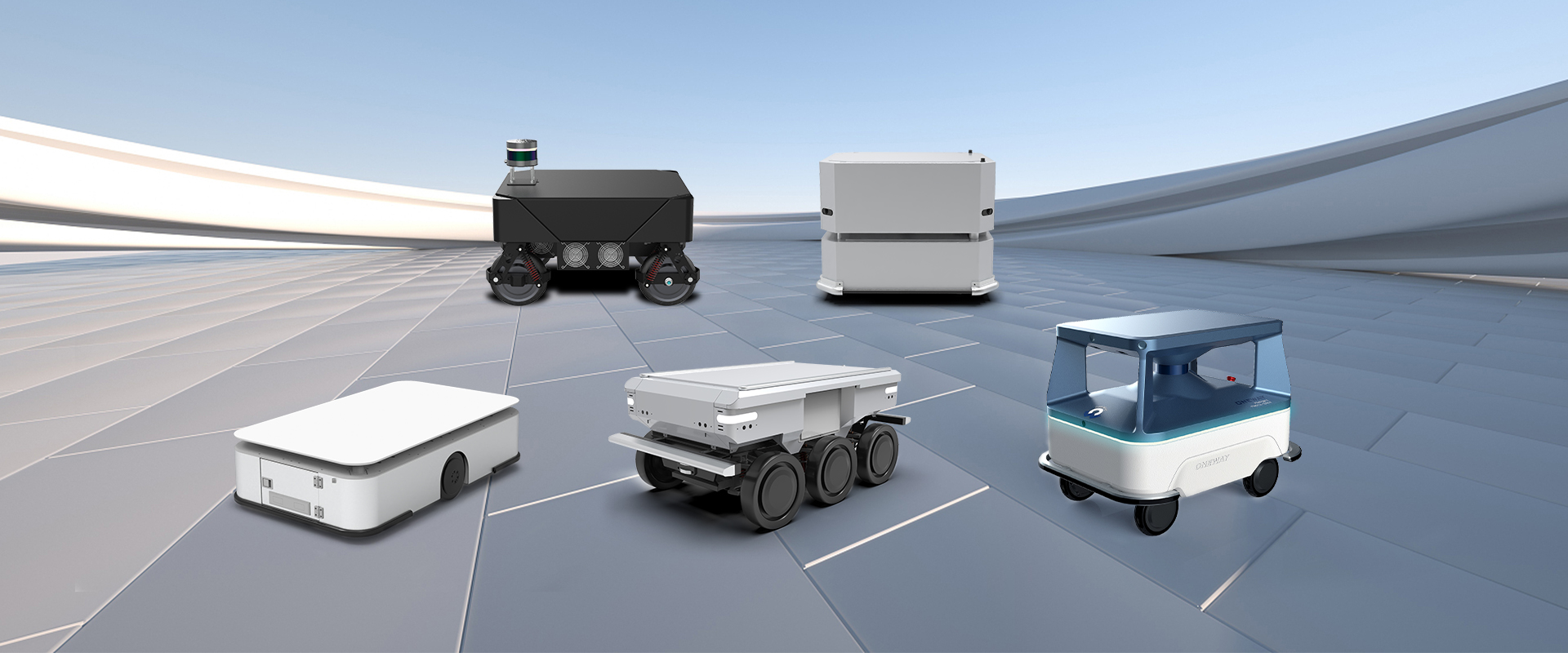

Another area where robotics has made significant strides is chassis robotics in manufacturing plants. These automated systems have transformed traditional assembly lines into highly efficient production processes.

Chassis robotics streamline repetitive tasks such as welding or painting by replacing manual labor with precision machinery. Not only does this improve productivity, but it also ensures consistent quality throughout the manufacturing process. By reducing human error and increasing speed, chassis robotics contribute to cost savings and faster time-to-market for products.

Conclusion

The inspection robot, along with individualized services provided by companies like Oneway and the implementation of chassis robotics in manufacturing plants, are revolutionizing industries worldwide. These technological advancements not only enhance efficiency but also promote safety and accuracy in inspections while optimizing performance and reducing costs for businesses.

As we continue to embrace these innovations, it is clear that the future of inspections lies in automation and customization. The possibilities are endless as we strive to create a more efficient and productive world through technology.