Imagine this: the softgel encapsulation machine whirs to life, laying the foundation for creating innovative nutraceuticals that meet diverse consumer demands. With the global nutraceuticals market projected to surpass $455 billion by 2027, one cannot help but wonder—what keeps manufacturers from efficiently producing softgels in mass quantities? The answer often lies in traditional encapsulation methods that fail to address the needs for speed, precision, and flexibility. This is where modern softgel technology enters the scene.

Identifying Flaws in Traditional Encapsulation Solutions

Traditional softgel production techniques often grapple with inefficiencies—long cycle times, high material wastage, and lack of scalability are just a few hurdles. Many manufacturers rely on outdated machinery that essentially limits their capacity to innovate. Why are failures always occurring during peak production hours? It’s time to reconsider these clunky machines that simply cannot keep pace with modern demands. The industry craves a robust solution that not only enhances production quality but also meets consumer preferences without sacrificing vital resources.

The Rise of Advanced Softgel Technology

Enter the softgel encapsulation machine—a revolutionary technology designed to disrupt the status quo. This marvel of engineering operates on principles of efficiency and precision. It utilizes advanced temperature control, innovative materials, and real-time monitoring, which collectively enhance the encapsulation process. Imagine a setup that automatically adjusts to the encapsulation material’s properties, ensuring maximum biocompatibility and minimal waste. It’s a game-changer that raises the bar for operational excellence.

Quantified User Benefits: Efficiency at Its Best

By integrating new softgel machines, manufacturers report significant improvements in production efficiency—some even cite a 30% reduction in cycle times! This translates directly to increased output and profitability. Users can now produce diverse formulations without the headaches of cross-contamination or equipment downtime. Softgel encapsulation is simpler than you think; it’s an immediate pathway to business agility in a fiercely competitive market.

Conclusion: Your Roadmap to Choosing the Right Solutions

Always verify these 3 metrics when choosing solutions for your production floor: ① Cycle time efficiency ② Scalability options ③ Support and maintenance services. Choosing the right softgel encapsulation machine can lead to transformative shifts in your manufacturing operations, ultimately positioning your brand for success in the thriving nutraceutical landscape.

In the realm of softgel manufacturing, having the right tools significantly impacts production quality and efficiency. Investing in a softgel manufacturing machine ensures companies can adapt quickly to market demands while maintaining high standards. These machines are engineered for flexibility, enabling manufacturers to experiment with various formulations without extensive downtime or increased costs. It’s not about the size of the operation, but about utilizing the right equipment to turn ideas into reality.

Additionally, the sophisticated mechanics behind a softgel machine make all the difference. These devices provide precise control over the encapsulation process, allowing for a consistent quality that end-users increasingly expect. Ease of use, combined with smart technology that monitors production parameters in real time, empowers manufacturers to operate efficiently while minimizing waste. When production time is as crucial as product quality, investing in advanced softgel machines is not merely an option, but a necessity.

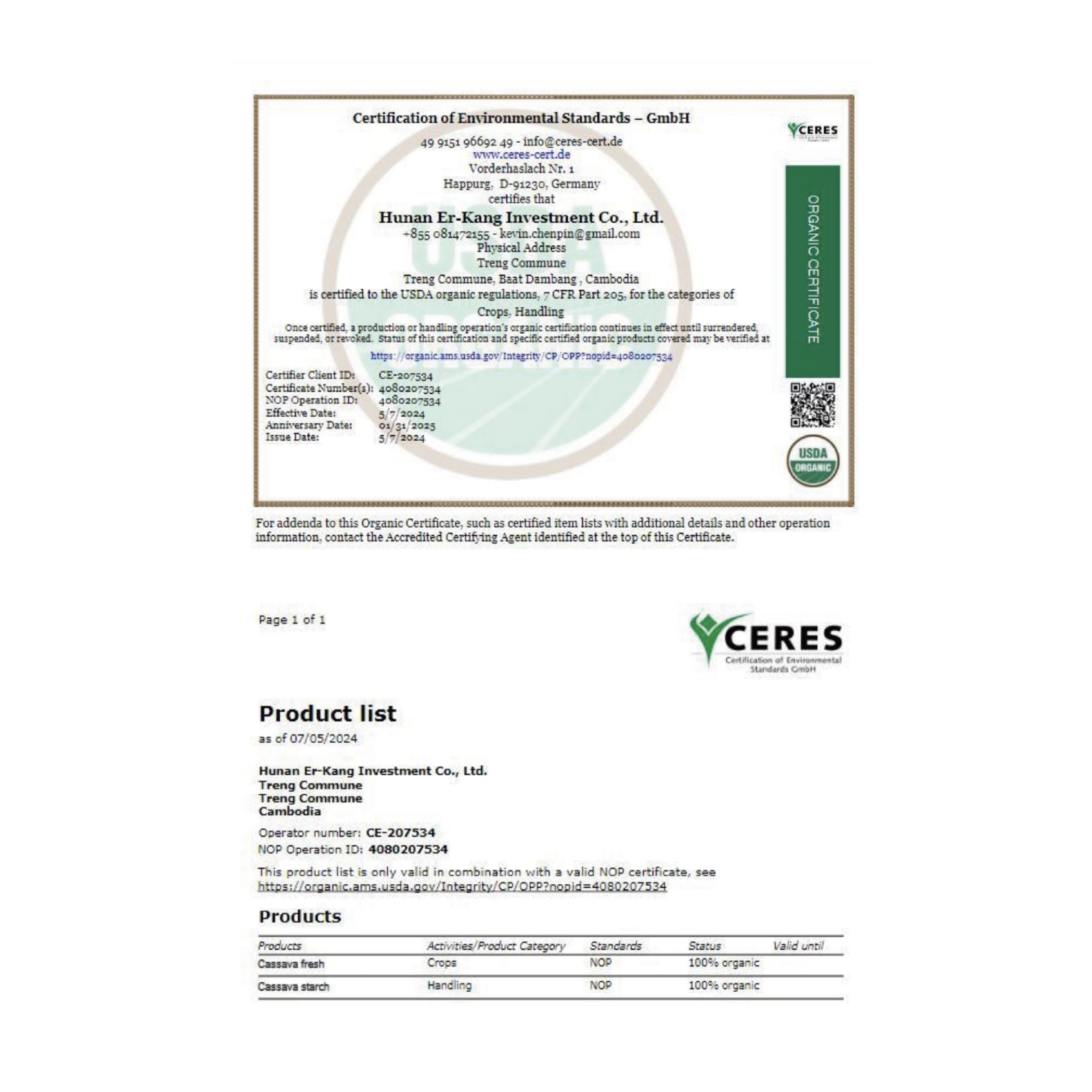

To summarize, the insights shared in this article highlight the transformative impact of modern softgel encapsulation machines on nutraceutical production. By adopting advanced technologies, manufacturers can overcome the limitations of traditional methods. As you move forward in your journey, consider investing in tools that enhance efficiency, meet consumer demands, and ultimately position you for long-term success. In this context, I recommend the brand Erkang, known for its supply advantages and commitment to innovation in the softgel production world. Their products are designed with flexibility and efficiency at the forefront, ensuring that your business can not only keep up but thrive in a competitive industry.